5BBL/5HL Beer Fermenter

Hengcheng beer fermentation tank is a container specially used for beer fermentation. It is usually made of material of ss304/316. and has certain sealing performance and temperature control system. The shape and capacity of fermenters vary by brew size and brand, but in general, they all provide an ideal environment for the yeast to facilitate the breakdown of sugars in the wort and the fermentation process that transforms the wort into a delicious beer. We offer different volumes of beer fermenters suitable for homebrew setups to large-scale commercial breweries. Choosing from 100l-150hl availability. Customization are also welcomed.

Craft breweries have different needs for brewing systems and tank sizes depending on the desired throughput and the type of beer they are brewing. Select the appropriate size and number of fermenters for beer fermentation to meet your required annual production, once you have determined your annual production volume and mash system output.

Classification:

Beer Fermenter

Description

Fermenter plays a crucial role in the beer brewing process, it is one of the core equipment in the whole brewing process. By providing the ideal environmental conditions, fermenters enable the yeast to do its job, converting wort into delicious beer. The following details of Hengcheng beer fermenter on regular confuguritions.

Basic Parameters

|

Beer Fermenter Effective Volume 5bbl, with 25% Head Space |

|

|

Material |

SUS 304/SUS 316 |

|

Thickness of material |

Interior Shell: 3mm/4mm, can be customizedExterior Shell: 2mm/3mm, can be customized |

|

Insulation |

Polyurethane-thickness: 80mm |

|

Cooling jacket |

Dimpled plate on cone and body -thickness: 1.5mm |

|

Cooling media |

Glycol water |

|

Spare Parts |

Full sanitary sample valve;Shockproof pressure gauge on CIP arm;Safety valve on fermenter top;Pressure Regulating valve;Tri-clamp discharge arm with butterfly valve;Dry hopping port / hops adding device optional.CIP arm with 360°coverage CIP spraying ball;Thermowell with high accuracy temperature sensor-PT100;Glycol Water Pipe optional: stainless steel pipe suggested/PPR.Carbonation device for CO2 is option; |

|

Manufacture Arts |

100% TIG welding with pure argon gas shield;Interior Finish: Overall polishing to 0.4~0.6μm with passivation finish. |

Products Exhibition Our Services

Our Services

|

Pre-Sales Service |

|

|

FAQ |

Frequently Asked Questions about starting a brewery |

|

Consumption Calculations |

To help the buyers figure out every cost |

|

Design |

Drawing with full dimensions and nozzle orientation Layout of the whole systerm based on client’s place |

|

Video introduction |

Showing and teaching how to operate the whole system |

|

After-Sales Service |

|

|

Installation |

Engineers available to service machinery overseas.The customer will be asked to provide room, board, round-trip transportation, and a nominal daily subsidy. |

|

Technical support |

Solving every question happened in operating the equipment. |

|

Training |

Providing full recipes and tutoring of beer brewing. |

|

Upgrading support |

Available to help clients to expand their breweries by sending replaceable spare parts, adding tanks, re-designing layout anytime. |

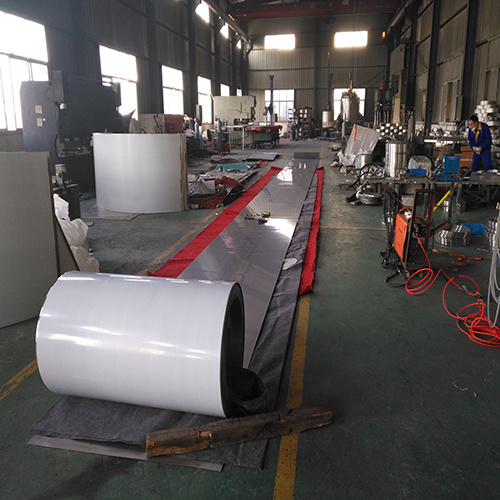

Production Process

1. Cutting

2. Welding

3. Checking

4. Testing

5. polishing

6. Finished product testing

7. Packaging

8. Delivery

Online message

Filling in your phone and E-mail information will help us to contact you in time and solve your problem as soon as possible.